Integrated polysilicon and wafer manufacturers will drive down costs by 6% next year.

Integrated manufacturers' costs. Image: NDP Solarbuzz.

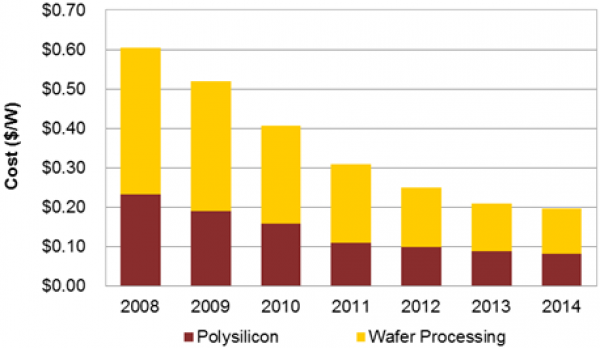

Manufacturing costs for tier one integrated polysilicon and PV wafer makers are set to hit a record low of US$0.20 per watt in 2014, according to analysis by NPD Solarbuzz.

The market research firm said that although the predicted 6% fall in costs next year will not equal the average 16% decrease they have seen annually since 2008, a hugely competitive market will continue to spur manufacturers to drive down costs.

“Wafer costs are only a third of what they were five years ago, and even though the rapid pace of cost reduction is starting to decline, the severe oversupply and extremely low selling prices are forcing polysilicon and wafer makers to continue to find ways to lower costs to previously assumed impossible levels,” said Charles Annis, vice president at NPD Solarbuzz.

According to Solarbuzz, manufacturers are relocating their polysilicon operations to areas with low electricity costs and replacing manufacturing capacity using the so-called Siemens manufacturing process with fluidised bed reactor (FBR) plant. Solarbuzz said manufacturers had reported being able to cut costs using FBR to less than US$10 per kilogram.

“At the same time, wafer makers are also reducing costs by increasing the multicrystalline ingot size from Gen 4/5 to Gen 6/7, reducing slurry consumption and increasing recycling, adopting diamond wire sawing for monocrystalline applications, and benefiting from rising conversion efficiencies as crystallisation quality continues to improve,” added Annis.

With Solarbuzz having recently forecast end-market demand to reach 45-50GW next year, the firm said further cost reductions should help manufacturers return to profit. It said at such levels of demand the seven polysilicon manufacturers it regards as ‘tier one’ – GCL Poly, Hemlock, OCI, REC Silicon, SunEdison, Tokuyama and Wacker – are all likely to return to high utilisation rates, helping pay back fixed costs.

And Solarbuzz said increasing demand should also shore up polysilicon and wafer prices, possibly even pushing them up, though this is likely to be dampened by “extreme” competition and tight production capacity.