LDK Solar becomes largest wafer producer: outlines technology roadmap

Apr 20, 2010 - Mark Osborne - pv-tech.org

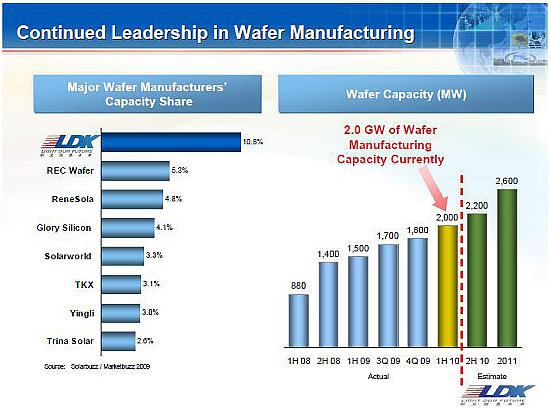

At an investor event held at LDK Solar’s main solar wafer manufacturing complex in Xinyu City, China, the rapidly scaling integrated PV producer noted that it has reached an annualized wafer capacity of 2GW, claiming to be the largest solar wafer producer in the world. In a series of presentations the company highlighted that wafer capacity will rise to 2.2GW in the second half of 2010, reaching 2.6GW by the end of 2011. The company also updated plans for polysilicon production and manufacturing costs as well as solar cell production start-up and ramp. Significantly, LDK gave insight into its technology roadmap plans that include multicrystalline solar cell efficiency targets of between 19 and 21% in 2014. At an investor event held at LDK Solar’s main solar wafer manufacturing complex in Xinyu City, China, the rapidly scaling integrated PV producer noted that it has reached an annualized wafer capacity of 2GW, claiming to be the largest solar wafer producer in the world. In a series of presentations the company highlighted that wafer capacity will rise to 2.2GW in the second half of 2010, reaching 2.6GW by the end of 2011. The company also updated plans for polysilicon production and manufacturing costs as well as solar cell production start-up and ramp. Significantly, LDK gave insight into its technology roadmap plans that include multicrystalline solar cell efficiency targets of between 19 and 21% in 2014.

"I am proud of the way our team has successfully executed  one of the most impressive capacity ramps in the sector," noted Xiaofeng Peng, Chairman and CEO of LDK Solar. "As the solar industry emerges from a challenging period, we are pleased to grow our capacity to meet the rebound in customer demand. We look forward to providing updates on our future progress as we strive to be a leader in wafer manufacturing." one of the most impressive capacity ramps in the sector," noted Xiaofeng Peng, Chairman and CEO of LDK Solar. "As the solar industry emerges from a challenging period, we are pleased to grow our capacity to meet the rebound in customer demand. We look forward to providing updates on our future progress as we strive to be a leader in wafer manufacturing."

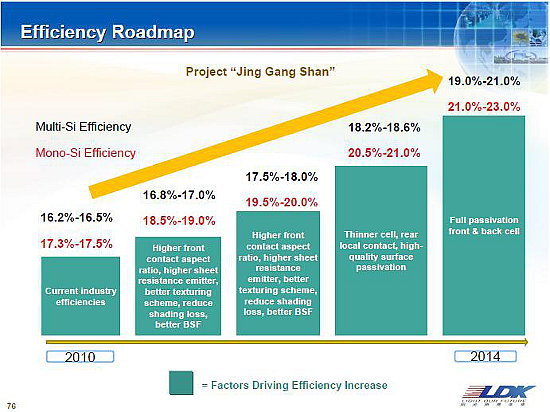

LDK Solar said that the cost-effective manufacturing of high efficiency solar cells will occur through adapting high-efficiency structure features with advancement in equipment and materials via mass production.

Highlighted developments at the analyst event included the expected start of solar cell production in the third quarter, which will initially have a capacity of 60MW. However, LDK Solar plans rapid expansion to 240MW in the fourth quarter of 2010 and by the end of 2011 aims to reach a solar cell capacity of 480MW.

Cells are produced for its internal module requirements which will help to reduce module costs as the ramp increases through the year. The company is targeting a cell processing cost reduction of approximately 15% in 2010 and again in 2012. In 2013, the cost reductions will be targeted at approximately 10%. Cost reductions will br brought about by expanding capacity, improving conversion efficiencies as well as low material costs, primarily by sourcing more than 50% of materials from within China, the company said.

A 60MW high-efficiency solar cell R&D line is also being established to coordinate technology developments from bare wafer through to modules. Wafer thickness is expected to be reduced to between 130 and 160 microns in the next five years.

In 2011, solar cells are expected to employ higher front-contact aspect ratio, higher sheet resistance emitter, better texturing scheme and reduced shading loss capabilities. The following year, the company expects to introduce cells with even higher front contact aspect ratio, higher sheet resistance etc. In 2013, LDK Solar is targeting thinner cells, rear local contacts and a high quality surface passivation. In 2014, cell efficiencies of multicrystalline solar cells would reach an expected 19 to 21% performance with monocrystalline cells reaching 21 to 23% conversion levels.

Module production capacity targets were reiterated for 2010 at 1.5GW with the target of 2GW by the end of 2011. Like cell production cost reductions, LDK Solar expects module production costs to decline by 10 to 15% in 2010.

|